FDM 3D Printer printing FAQ

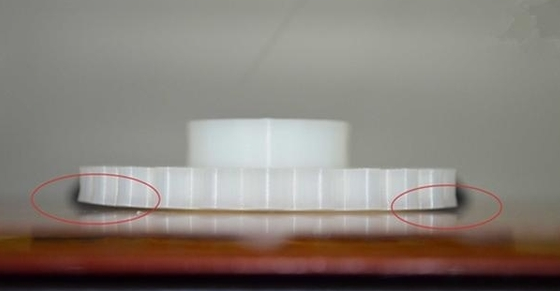

1, Wrapping

Edge warping occurs when the plastic cools and shrinks. When the printed object cools and begins to shrink, the bottom of the object will bend and warp, and it may also prevent the object from sticking to the printing platform. The best way to avoid warping is to assemble a heating plate to maintain the temperature of the bottom of the printed object above the glass transition temperature, so that the object cannot be completely cooled into a solid, so that it can be well attached to the platform. Usually the heating plate is sufficient, but it is also recommended to use solid glue or textured paper to increase the adhesion. First apply a thin layer of solid glue on the platform, and then spread it with a damp cloth or paper. After heating and evaporating water vapor, a thin solid glue will be left on the platform.

2, Distance between nozzle and platform

Whether the first layer can be extruded well and attached to the printing platform is very important. If the distance between the platform and the nozzle is too far, the extruded wire will not be able to adhere to the platform well; if the distance between the platform and the nozzle is too close , The wire will not be extruded from the nozzle. The following photos are the ideal state of wire extrusion:

In the photo, the wires are uniform in thickness and in good contact with each other. If there is a gap between your wires, it means that the platform is too far away from the nozzle; if the wires are flattened and the contact between the wires is messy, it means the platform is too close to the nozzle.