How to design parts for FDM 3D printing

How to design parts for FDM 3D printing?

What is FDM 3d printing process?

FDM 3D printing is an additive manufacturing process that uses the technique of material extrusion. Also known as fused filament fabrication (FFF), FDM is the most widely used 3D printing technology.

As the most affordable 3D printing technology on the market, fused deposition modeling (FDM) is an excellent choice for rapid, low-cost prototyping and can be used in a variety of applications.

Like all manufacturing methods, FDM has some limitations and restrictions on what can be printed. Now we cover how to adjust your design for optimal FDM print quality.

How to design FDM 3d printing?

To achieve the best results, keep FDM’s capabilities and constraints in mind when designing a part for FDM 3D PRINTING.

Bridging

Bridging in FDM occurs when the printer is required to print between two supports or anchor points.

Because there is nothing to build on, no support is offered for the initial layer being printed and the material tends to sag. Bridges most often occur in horizontal-axis holes found in the walls of objects or in the top layer (or roof) of hollow parts.

One solution is to reduce the distance of the bridge, but the impact of this depends on the part’s design constraints.

Another solution to avoid sagging is to include support. Support offers a temporary platform for the bridging layer to be built upon. The support material is removed once the print is completed, although it can leave marks on or damage the surface where the support was connected to the final part.

Key design consideration: Due to the nature of FDM, sagging or marks from support material are to some extent always present unless the bridge is less than 5mm.

If a smooth, level surface is required, an advanced solution is to split the design into separate parts or do some form of post-processing.

Vertical shaft hole

FDM often prints vertical shaft holes that are undersized. The printing process of such holes and the reasons for their diameter reduction can be summarized as follows:

As the nozzle prints the perimeter of the vertical axis hole, it compresses the newly printed layer down onto the existing build layer to help improve adhesion.

The compressive force of the nozzle deforms the shape of the extruded circular layer from a round shape to a wider, flatter shape.

This increases the contact area with the previously printed layer, improving adhesion but widening the extrusion section.

This results in a smaller printed aperture. This reduction can be a problem, especially when printing small diameter holes, where the effect is greater due to the ratio of hole diameter to nozzle diameter.

The amount of undersize depends on the printer, slicing software, hole size and material.

The reduction in diameter of vertical axis holes is often taken into account by the slicing program, but accuracy can vary. Several test prints may be needed to achieve the desired accuracy. If a high level of accuracy is required, it may be necessary to drill the hole after printing.

Key design consideration: If the diameter of the vertical axis hole is critical, the recommendation is to print it undersized and then drill the hole to the correct diameter.

Overhang

Overhang issues are one of the most common FDM print quality issues. Drapes occur when a layer of printed material is only partially supported by the layer below. As with bridging, insufficient support provided by the surface beneath the build layer can result in poor layer adhesion, swelling, or curling.

Depending on the material, overhangs of up to 45° can usually be printed without compromising quality. At 45°, the newly printed layer is supported by 50% of the previous layer. This creates enough support and adhesion to build with.

Above 45°, support is required to ensure that the newly printed layer does not bulge downward and away from the nozzle.

Another problem that arises when printing overhangs is curling. Newly printed layers become increasingly thinner at the overhanging edges. This causes uneven cooling, causing it to deform upwards.

Key design considerations: You can overcome the limitations of overhangs by using supports for wall angles above 45°. For larger overhangs that require support, marks will appear on the final surface unless post-processed.

Corners

Since FDM printing nozzles are round, the radii of the corners and edges are equal to the nozzle size. This means the features will never be perfectly square.

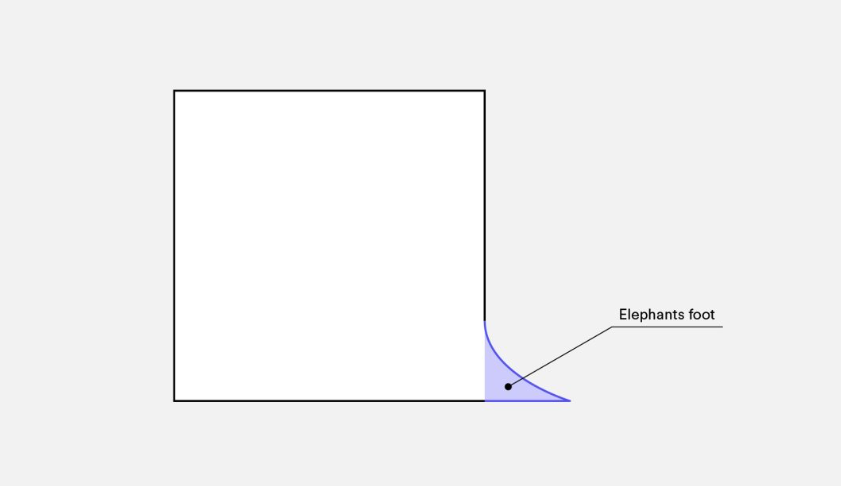

The first layer of printing is especially important for sharp edges and corners. As discussed above for vertical holes, for each printed layer, the nozzle compresses the printed material downward to improve adhesion. For the initial print layer, this creates a flare often called an "elephant foot."

The flare protrudes beyond the specified dimensions and affects the ability to assemble the FDM part.

Another common problem with FDM printing the first layer is warping. Compared with PLA, ABS is more prone to warping due to higher printing temperatures. The bottom layer is the first layer to be printed. It cools as other thermal layers print on top. This results in uneven cooling and may cause the base layer to curl away from the build plate as it shrinks.

Adding chamfers or radii along the edges of parts that come into contact with the build plate can reduce the impact of these issues. This also facilitates removal of components from the build plate after the print is complete.

Key design consideration: If assembly or overall dimensions are critical to the functionality of the FDM part, include a 45° chamfer or radius on all edges that contact the build platform plate.

Vertical pin

Vertical pins are often printed using FDM when parts need to be assembled or aligned. It is crucial to know the size of the vertical pins that FDM can accurately print, as these features are often useful.

Large dowels (larger than 5mm in diameter) are printed with perimeter and padding to provide a strong connection to the rest of the print.

Smaller diameter dowels (less than 5 mm in diameter) can consist only of peripheral printing without infill. This creates a discontinuity between the rest of the print and the pins, resulting in a weak connection that can easily break. In the worst case, a small pin may not print at all because there is not enough print material for the newly printed layer to adhere.

Proper printer calibration (including optimal layer height, print speed, nozzle temperature, etc.) often reduces the likelihood of pin failure. Adding a radius to the base of the pin eliminates stress concentrations at that point and increases strength. For critical pins less than 5 mm in diameter, off-the-shelf pins inserted into printed holes may be the best solution.

Key design consideration: If your design contains pins smaller than 5mm in diameter, add a small fillet to the bottom of the pin. If functionality is critical, consider including a hole in the design at the pin location, drill the hole to the correct size, and insert the off-the-shelf pins.

Tips for advanced FDM design

When printing with FDM, consider how to reduce the amount of support required, a part’s orientation and the direction the part is built on the build platform.

Splitting your model

Splitting a model can often reduce its complexity, saving costs and time. Overhangs that require a large amount of support may be removed by simply splitting a complex shape into sections that are individually printed. If desired, the sections can be glued together once printing is completed.

Hole orientation

The best way to avoid support for holes is by changing the print orientation. Removal of support in horizontal-axis holes can often be difficult, but rotating the build direction 90° eliminates the need for support. For components with multiple holes in different directions, prioritize blind holes, followed by holes with smallest to largest diameters and then the criticality of hole size.

Build direction

Due to the anisotropic nature of FDM printing, understanding the application of a component and how it is built are critical to the success of a design. FDM components are inherently weaker in one direction due to layer orientation.

FDM 3D printing best practices

If the bridge exceeds 5 mm, there may be sagging or marking of the support material. Splitting the design or post-processing can eliminate this problem.

For critical vertical hole diameters, drill holes after printing for greater accuracy.

Adding supports will allow the FDM printer to print wall angles greater than 45°.

Include a 45° degree chamfer or radius on all edges of the FDM part that contact the build plate.

For applications with small vertical pins, add a small fillet to the bottom, or consider inserting off-the-shelf pins into printed holes.

Splitting the model, reorienting holes, and specifying build directions are all factors that can reduce costs, speed up the printing process, and increase design strength and print quality.