Tips for advanced FDM 3d printing design

Tips for advanced FDM 3d printing design

When printing with FDM, consider how to reduce the amount of support required, a part’s orientation and the direction the part is built on the build platform.

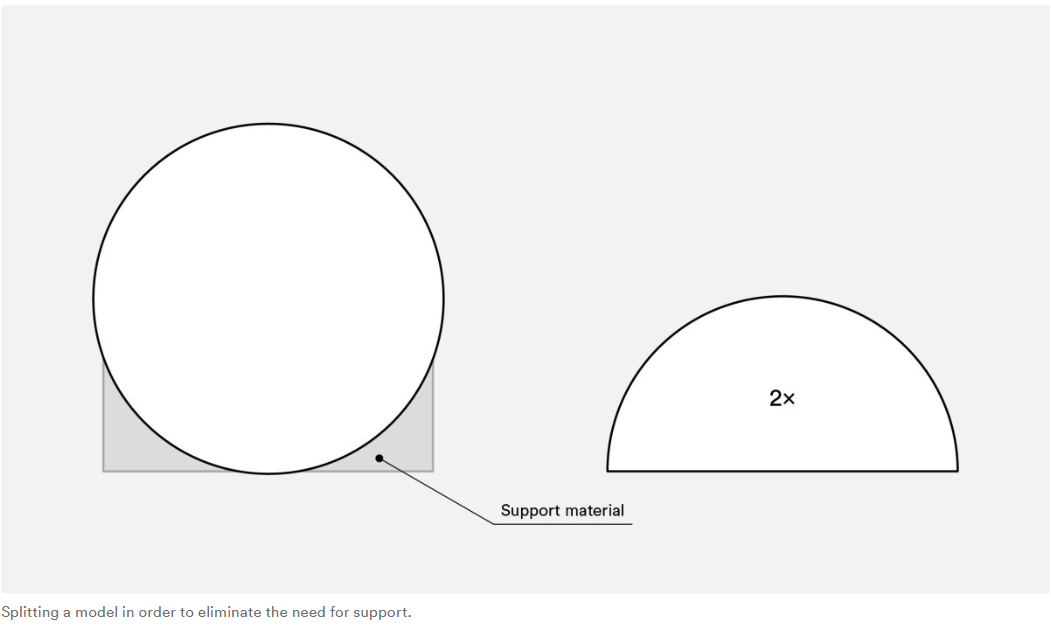

Splitting your model

Splitting a model can often reduce its complexity, saving costs and time. Overhangs that require a large amount of support may be removed by simply splitting a complex shape into sections that are individually printed. If desired, the sections can be glued together once printing is completed.

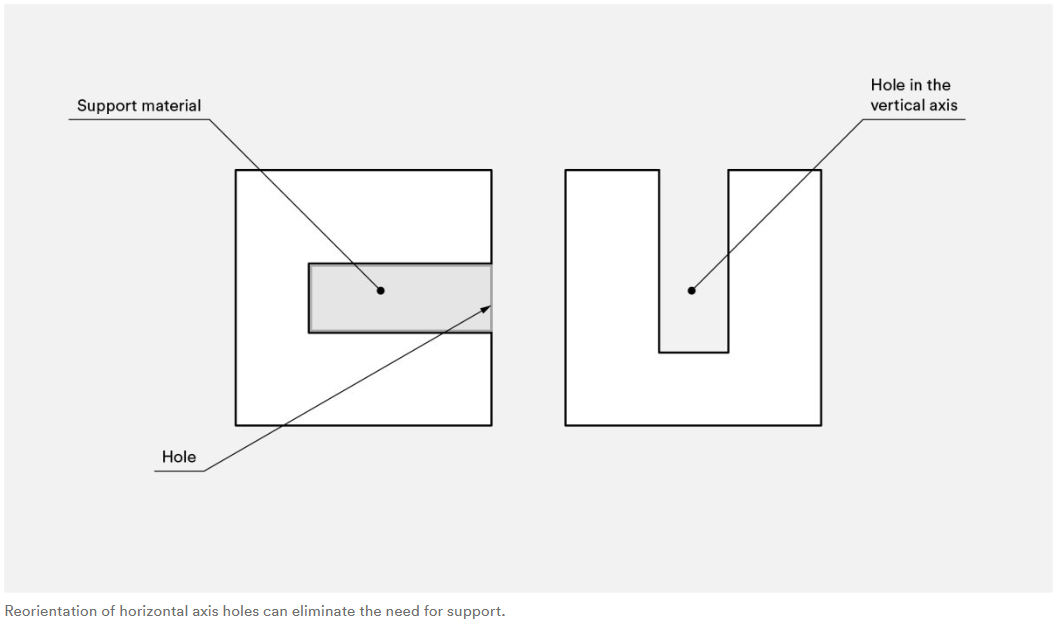

Hole orientation

The best way to avoid support for holes is by changing the print orientation. Removal of support in horizontal-axis holes can often be difficult, but rotating the build direction 90° eliminates the need for support. For components with multiple holes in different directions, prioritize blind holes, followed by holes with smallest to largest diameters and then the criticality of hole size.

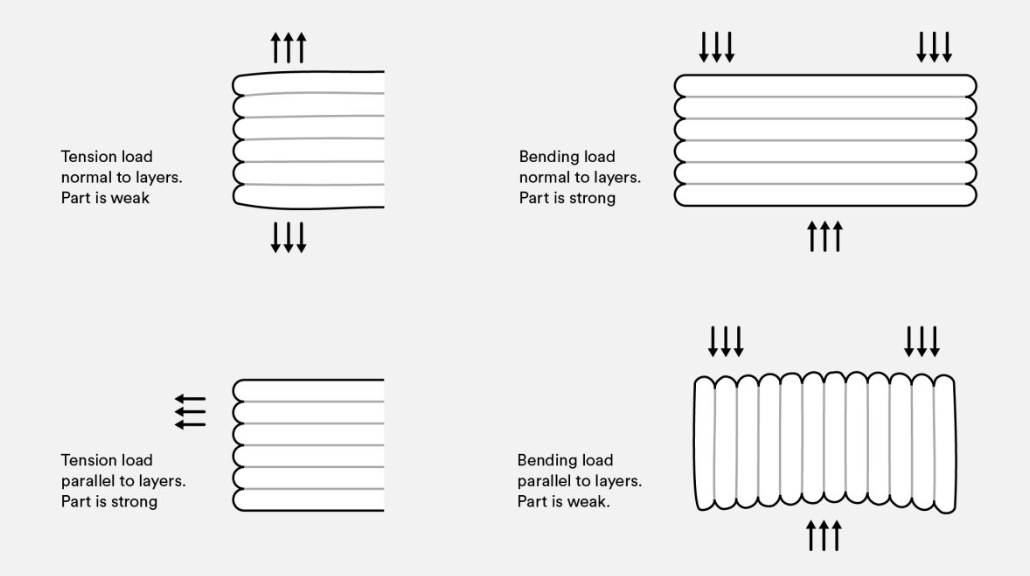

Build direction

Due to the anisotropic nature of FDM printing, understanding the application of a component and how it is built are critical to the success of a design. FDM components are inherently weaker in one direction due to layer orientation.

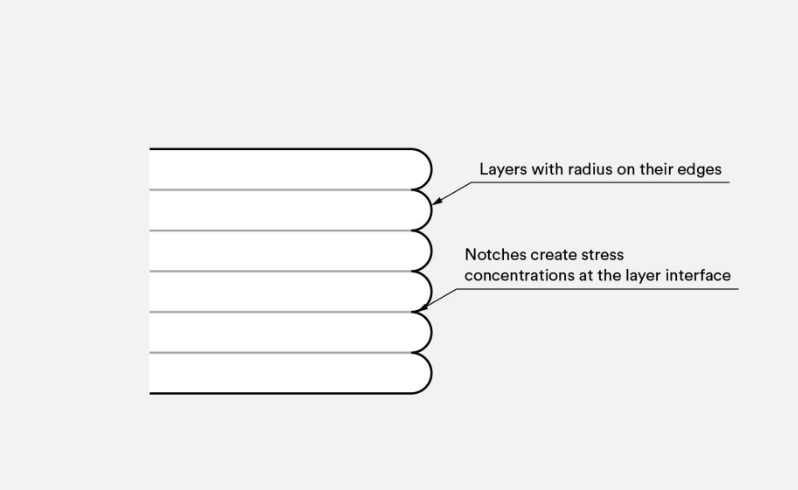

A lack of continuous material paths and the stress concentration created by each layer joint contribute to this weakness. Since the layers are printed as a round-ended rectangle, the joints between each layer are actually small valleys. This creates a stress concentration with a tendency to crack.

FDM 3D printing best practices

If a bridge exceeds 5mm, sagging or marks from support material can occur. Splitting the design or post-processing can eliminate this issue.

For critical vertical-hole diameters, drill after printing to achieve higher accuracy.

The addition of support will allow FDM printers to print wall angles greater than 45°.

Include a 45° degree chamfer or radius on all edges of an FDM part touching the build plate.

For applications with small vertical pins, add a small fillet at the base or consider inserting an off-the-shelf pin into a printed hole instead.

Splitting a model, reorienting holes and specifying build direction are all factors that can lower cost, accelerate the printing process and improve a design’s strength and print quality.

Contact us to get more 3d printing skills on industrial large 3d printers!