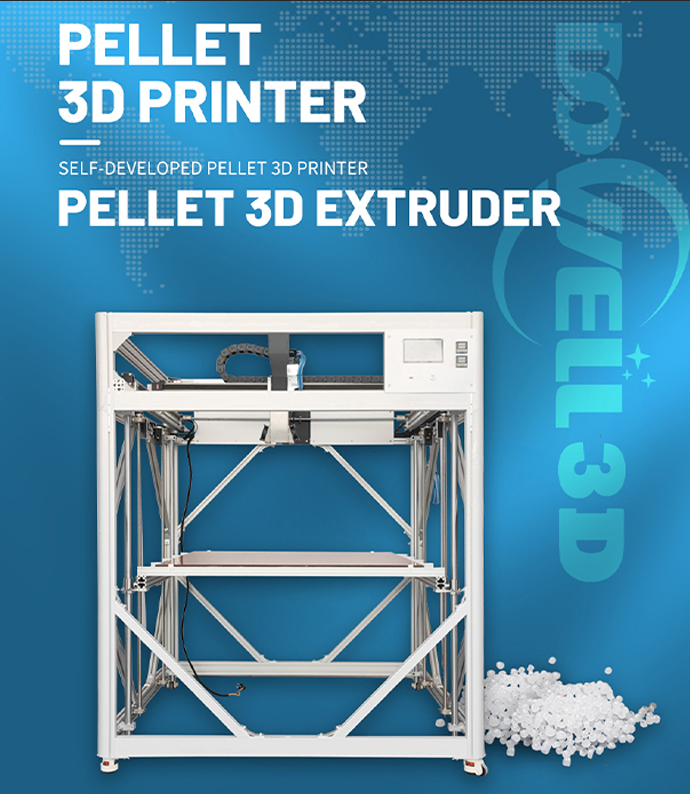

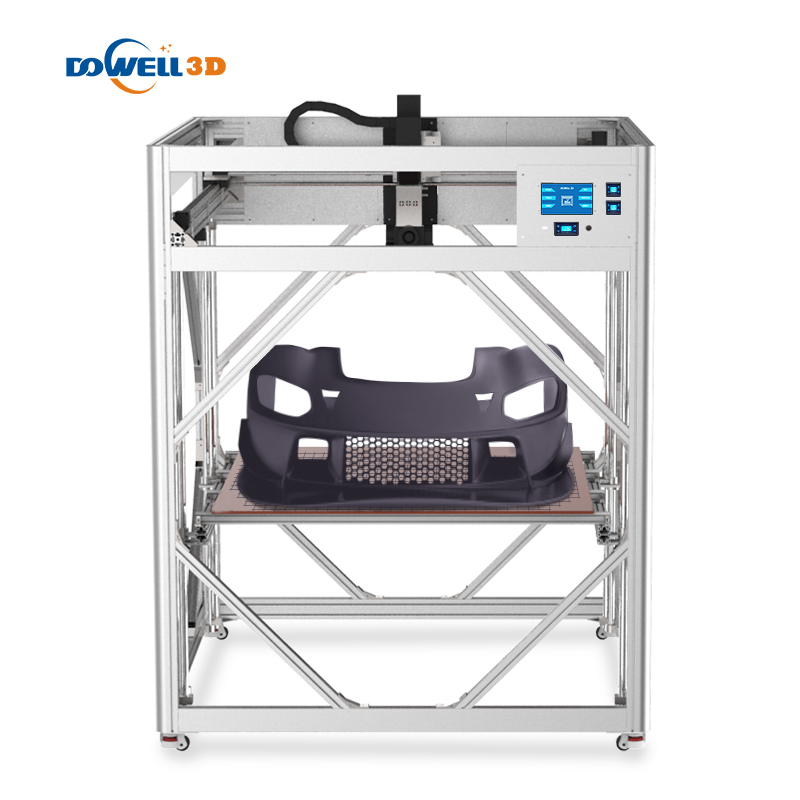

Giant 3D printer FAST speed particle pellet extruder 3d printer

- Dowell

- Luoyang

- 7-14days

- 1000 set/month

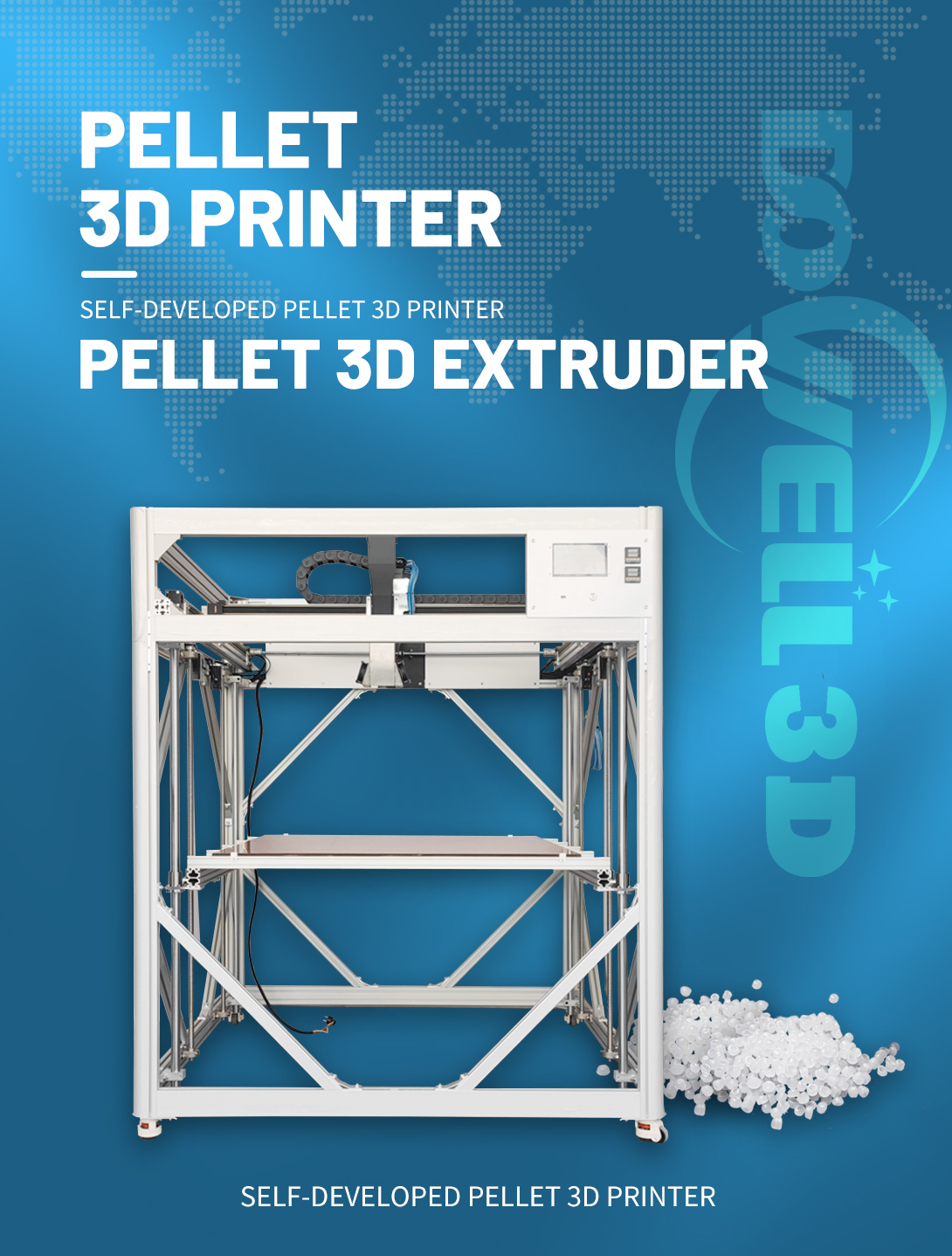

A variety of Dowell 3D printers that are built for Industrial Applications.

Our printers are able to print using Industrial Grade Materials and have larger Print Volume for any project.

Fast extrusion flow max can reach 4-5kg/hour, which is hundreds times than normal 3d printer.

A variety of Dowell 3D printers that are built for Industrial Applications.

Our printers are able to print using Industrial Grade Materials and have larger Print Volume for any project.

Fast extrusion flow max can reach 4-5kg/hour, which is hundreds times than normal 3d printer.

Advantages of Industrial Dowell 3D Pellet Printer

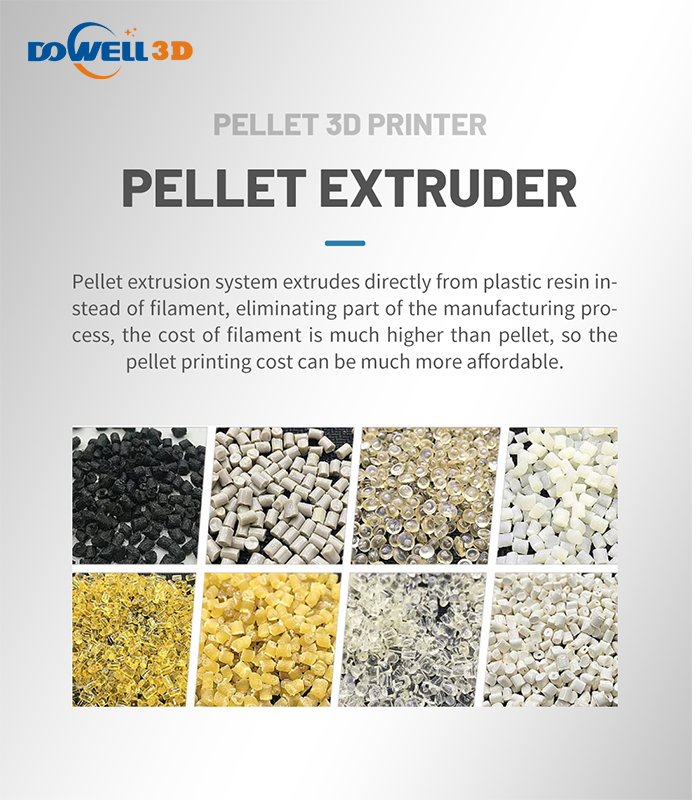

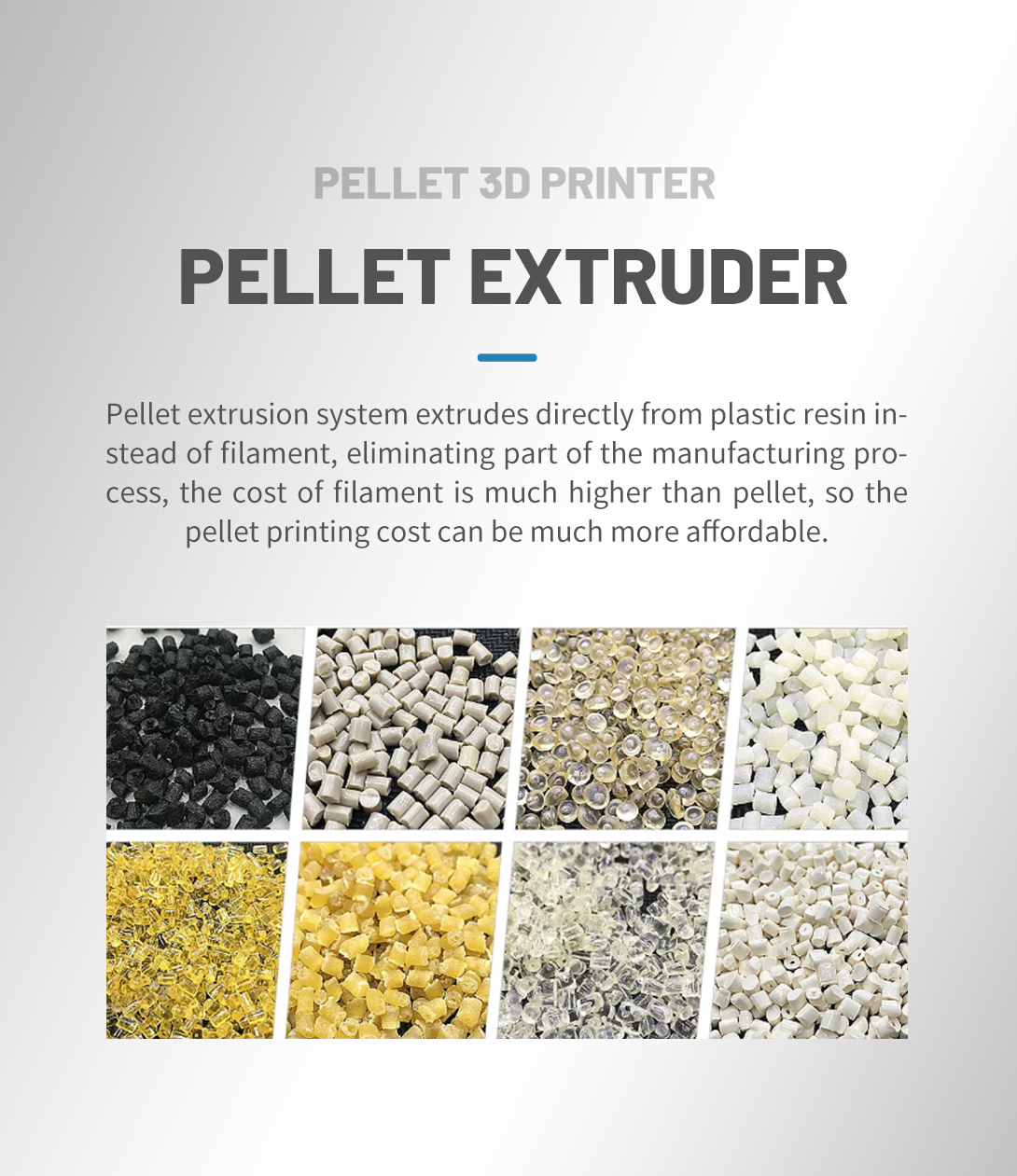

Cost Saving

Pellets can cost 65% to 90% less than filament of the same plastic.

Faster Extrusion Speeds

Pellet extrusion system which max can reach 4-5kg/hour nearly 100 times material throughput is possible compared to FDM printers.

Larger Print Sizes

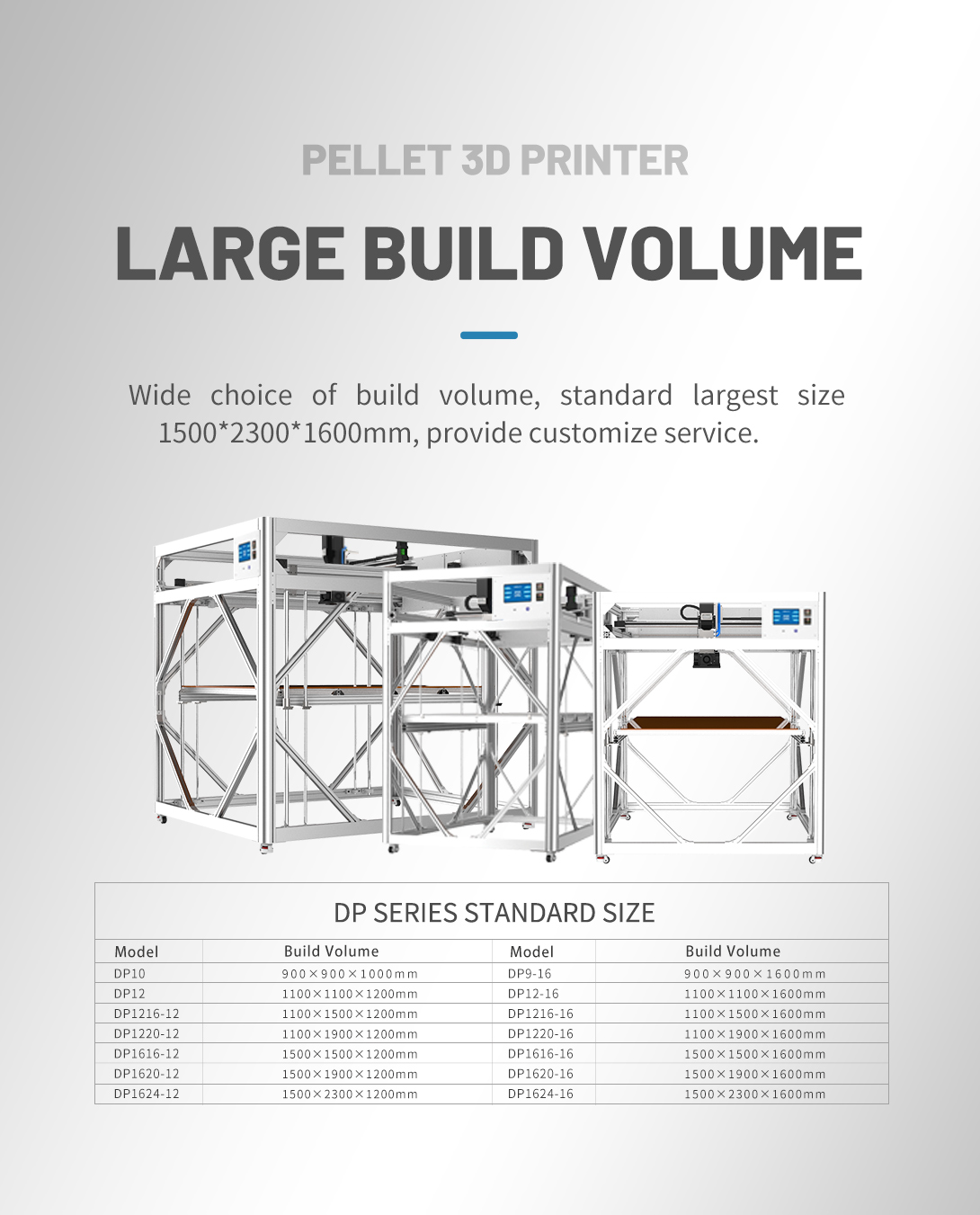

Industrial 3d printing usually requires a large 3D printer, Dowell 3d offer large size printer from 900*900*1000 to 1500*2300*1600mm and accept customization options.

Strong frame body

High quality aluminum alloy as the main body, super weight capacity.

Self-developed mainboard

High performance motherboard which developed by Dowell.

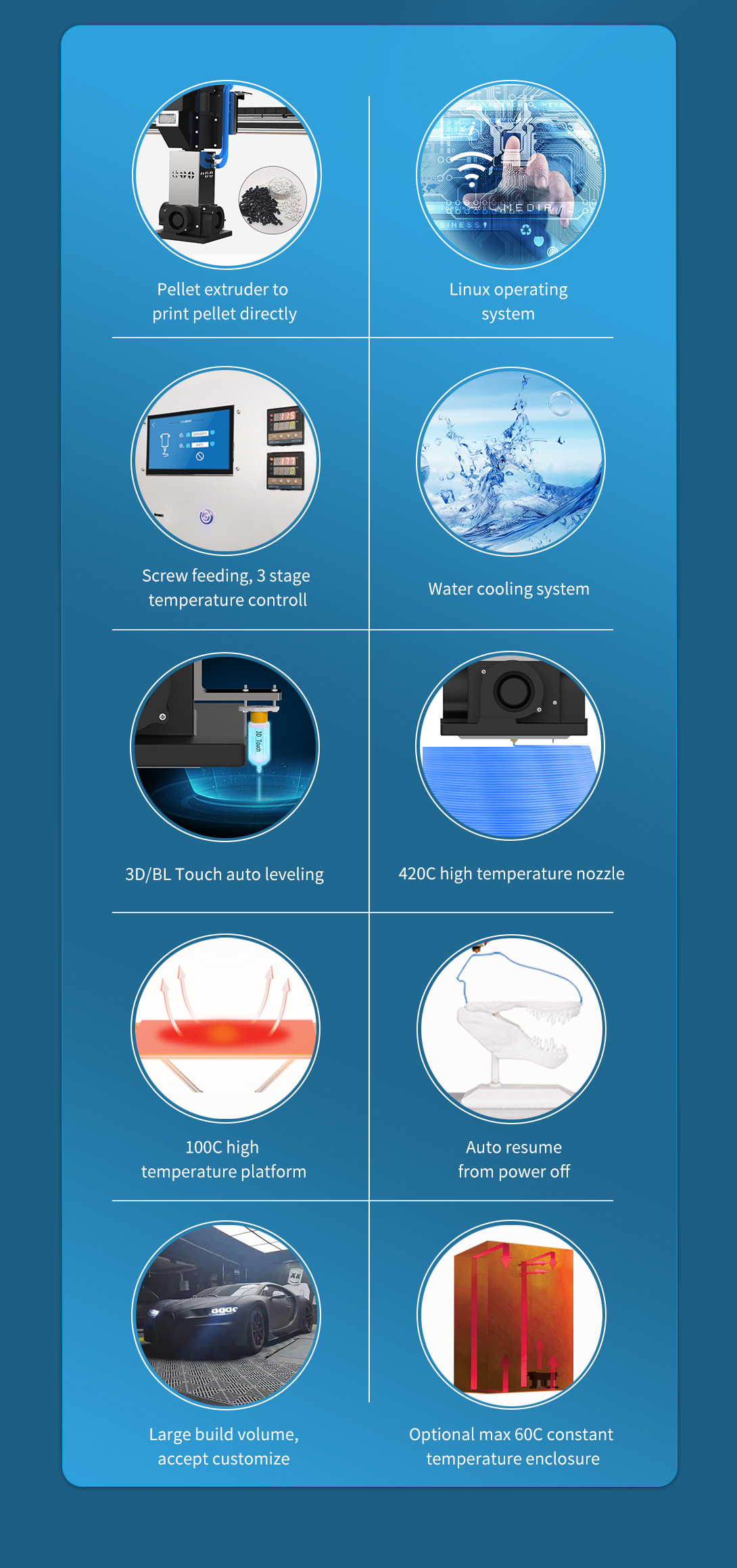

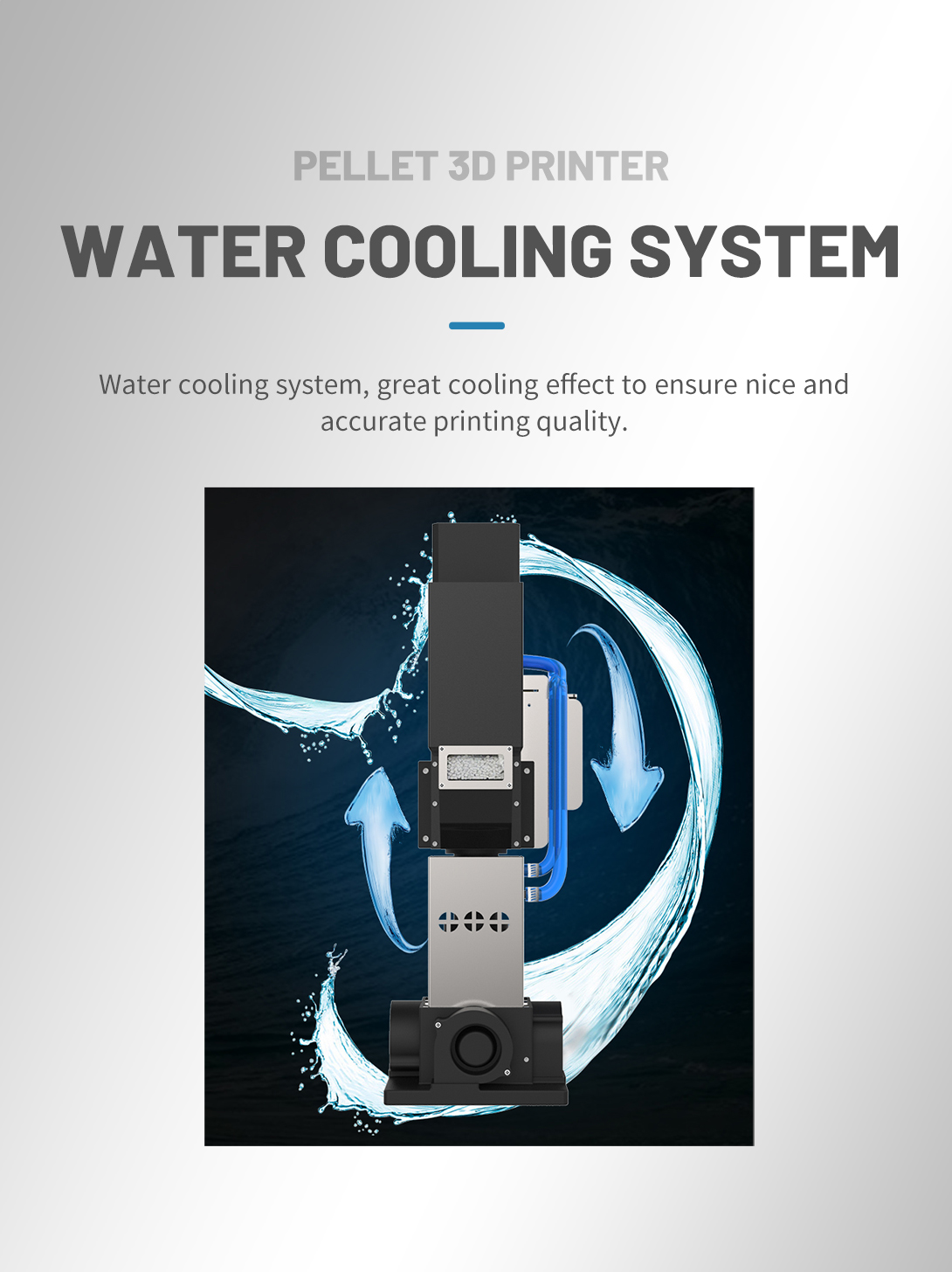

Water cooling system

Great cooling effect to ensure nice and accurate printing quality.

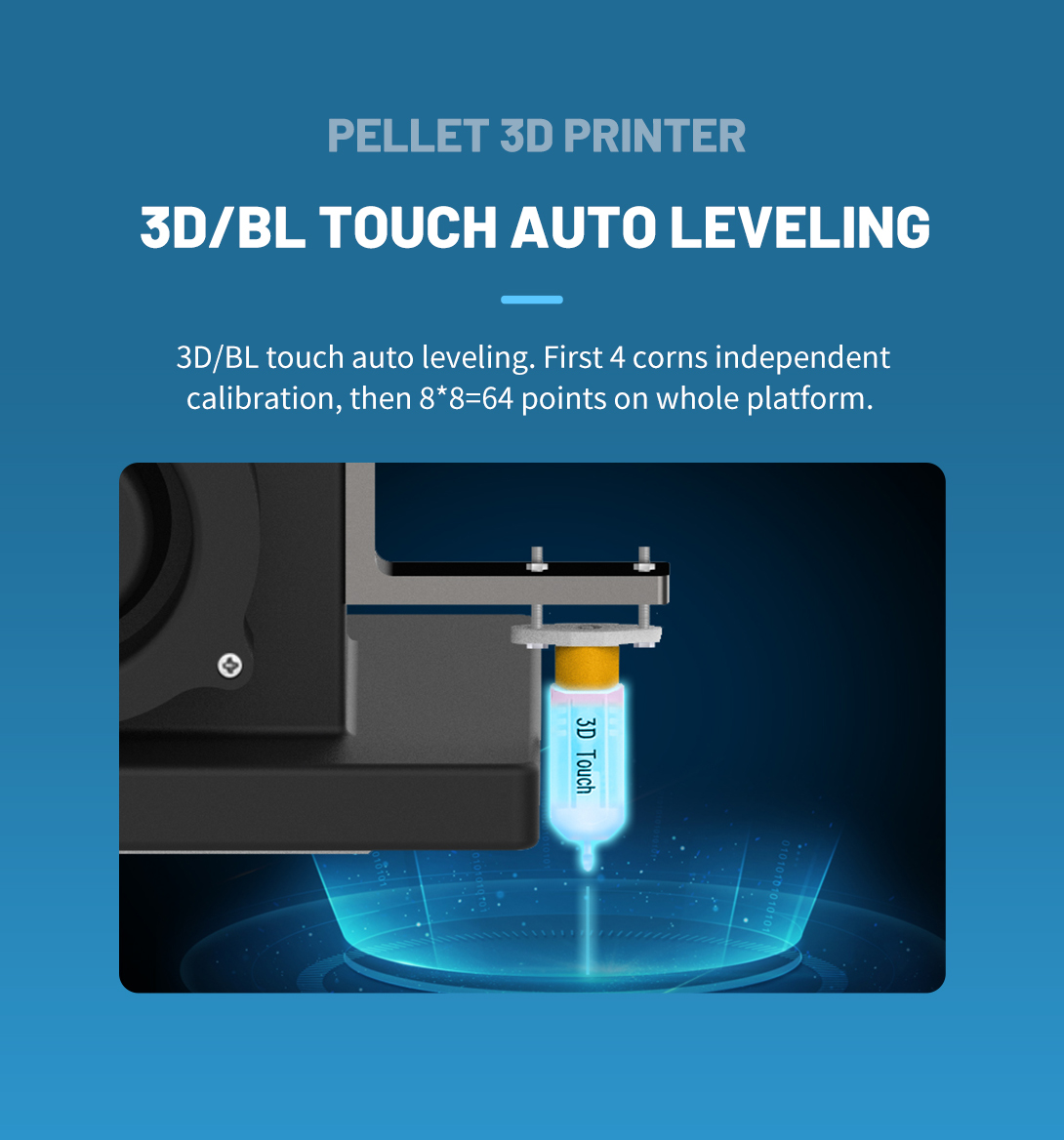

Automatic leveling

4 corner detection firstly, automatically adjust the platform to the basic level. Then, 64-point detection, Independent motor adjusts the screw rod to make the platform completely level easily and quickly

Linux System

Linux operating system which support remote control, much smarter

Custom Composites

Create own custom material blends by combining different pellets. You can easily add dyes, additives, and reinforcement fibers to the mix to create custom composite plastics.

Environmental Benefits

Someday, everyone will be chopping up their own household plastic waste to use in their 3D printer.

| Model | DP Series 3D Printer |

| Printing size | From 900*900*1000mm to 1500*2300*1600mm |

| Printing bed | 6mm tempered glass |

| Bed temperature | 0-100℃ (optional 150℃ ) |

| Nozzle size | 1mm-2mm-3mm |

| Nozzle temperature | 3 stage temp control |

| Slicing software | Dowell3d / Cura / or other similar software |

| Input format | STL/OBJ/Gcode/JPG |

| Basic function | Auto leveling, filament sensor, auto resume from power off, auto power off, nozzle anti-collision, etc... |

| Connection | U disk/ SD Card/ WIFI |

| Movement of X&Y | Module movement |

| Customization | Printing size, logo. |

Pellet extrudes plastic directly instead of filament, eliminating part of the manufacturing process, the cost of pellet much lower than filament.

6mm tempered platform, During the platform heating process, the platform will heating up rapidly and will not deform.

Using newest upgarde 7 inch full color touch screen, easy to poerate and rich functions.

Linux operating system which support remote control, make your printing work easy and fun.

Water cooling system, great cooling effect to ensure nice and accurate printing quality.

3 stage temperature control making extrusion smooth and accurate

Smart auto leveling to achieve ture automatic leveling.

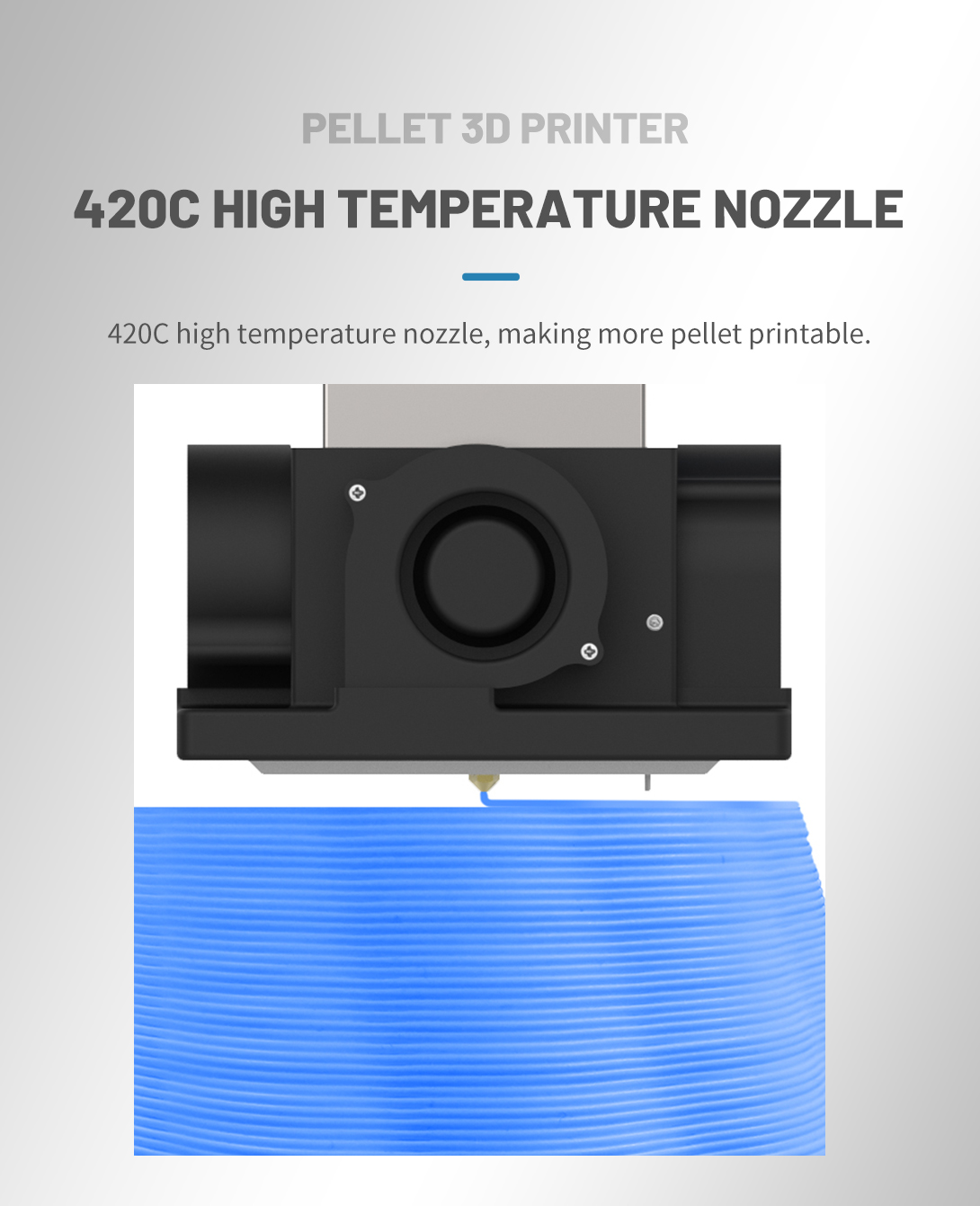

420 °c high temperature nozzle, more pellet material printable.

Auto resume from power off , when the power resume, the printer will find the right position to continue printing.

Multiple printer model for you choose from, besides we accept custom made printer size.

About Dowell 3D