Wholesale Car Body Kit DOWELL3D Plastic 3d Printer DP 5000g/hour high flow rate impresora architecture sculpture model printer 3d

- DOWELL3D

- China

- 10-16 days

- 1000pcs/month

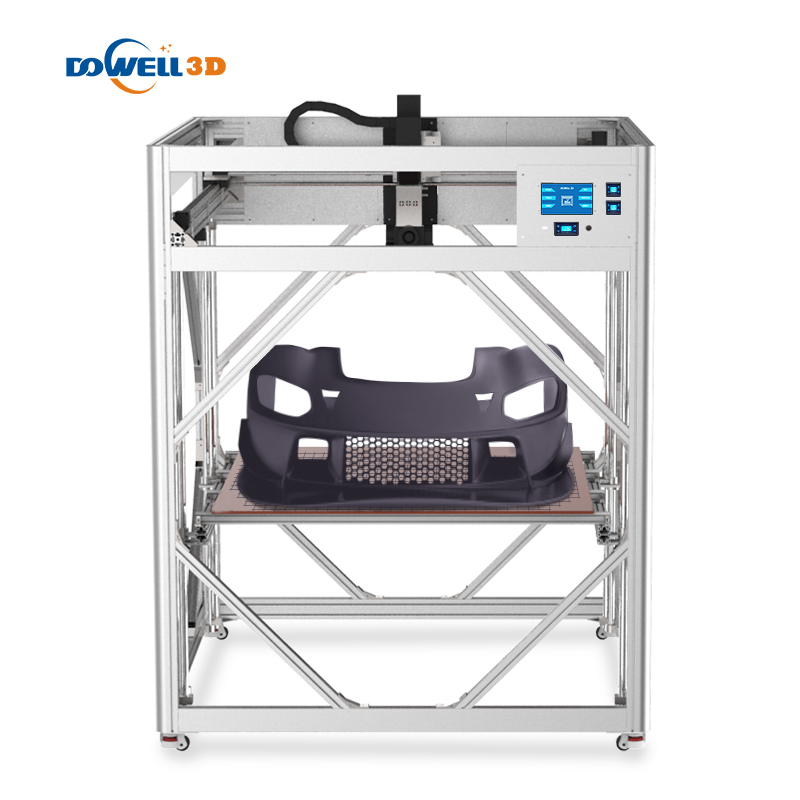

DOWELL3d DP printer directly transforms raw materials into granular form on the print bed. Specifically designed for large projects, it offers fast printing, low cost, and high strength. With three-stage screw extrusion for improved speed, cost-saving pellet technology reduces printing costs by 50% per kilogram, supporting multi-pellet printing. The printer is equipped with a separate water cooling and heat dissipation system for efficient cooling.

Wholesale Car Body Kit DOWELL3D Plastic 3d Printer DP 5000g/hour high flow rate impresora architecture sculpture model printer 3d

Specification of DOWELL3D DP Series Printer

| Product | DOWELL3D Pellet 3Dprinter DP Series | |||

| Frame | Thickened 80mm Aluminum Section | |||

| Nozzle Diameter | 1.0/2.0/3.0mm | |||

| Extruder | Screw Extrusion | |||

| Nozzle Temperature | 0-420℃ | |||

| Bed Temperature | 0-100℃ | |||

| Max Extrusion Flow Rate | 4000-5000g/hour | |||

| Extruder Cooling System | Water Cooling | |||

| Pellet | <φ4mm recommended | |||

| Operation Firmware | R&D Based on Klipper | |||

| Operation Interface | 7''full color touch screen | |||

| File Format | STL/OBJ/GCODE/JPG | |||

| Connection | SD Card/USB/WI-FI(optional) | |||

| Input Power | 110/220V | |||

| Basic Functions | *Auto leveling *Auto resume from power off *Auto power off | |||

| Optional | *150℃ Heating bed *60℃ Enclosure *Printing area *Based on Klipper Firmware *Automatic feeding system | |||

User's Feedback of DOWELL3D Printer

Product Description of DOWELL3D DP Series Printer

Why Choose DOWELL3D DP Pellet Printer?

DOWELL3d printer converts raw material directly to the print bed in a granular form.

It's designed to print big projects, resulting in shorter turnaround times and more

reliability with low material cost, fast printing speed and the product is with high strength.

Pellets Cost Savings

*50% Reduction in printing cost per kilogram

*Pellets are more cheaper, Multi-pellet printable

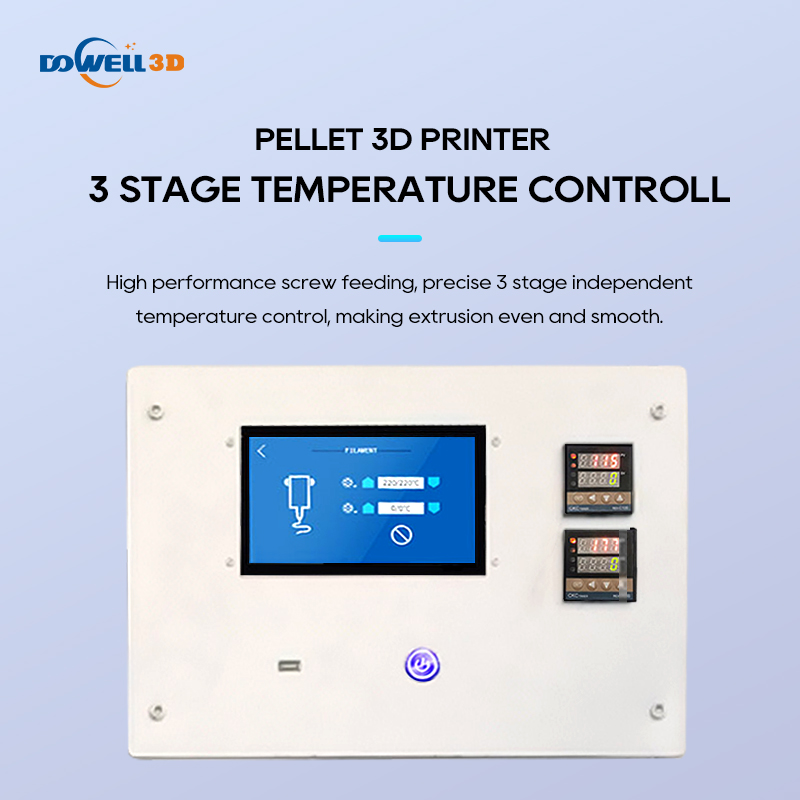

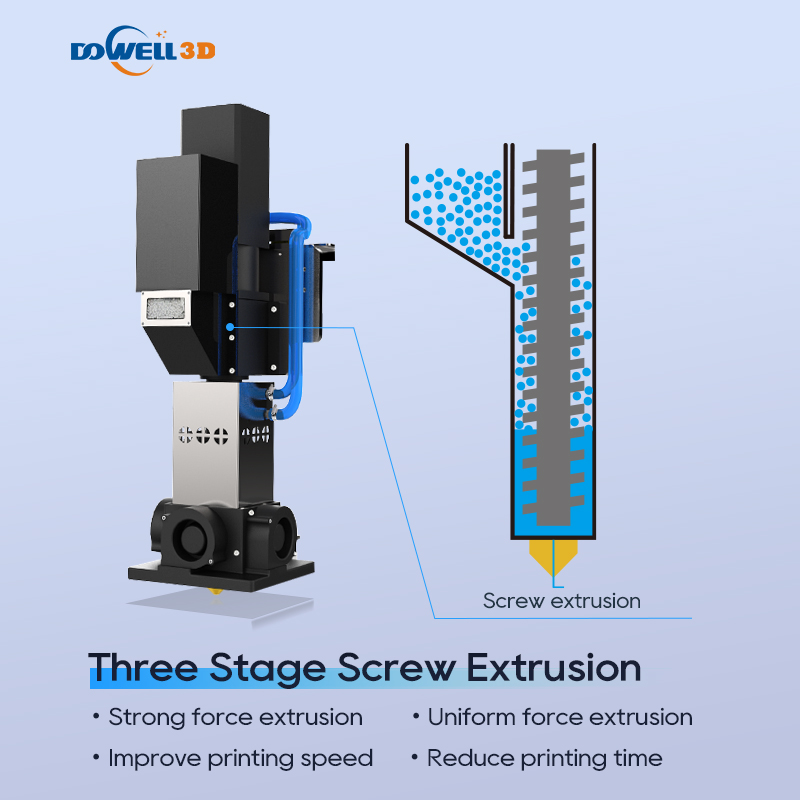

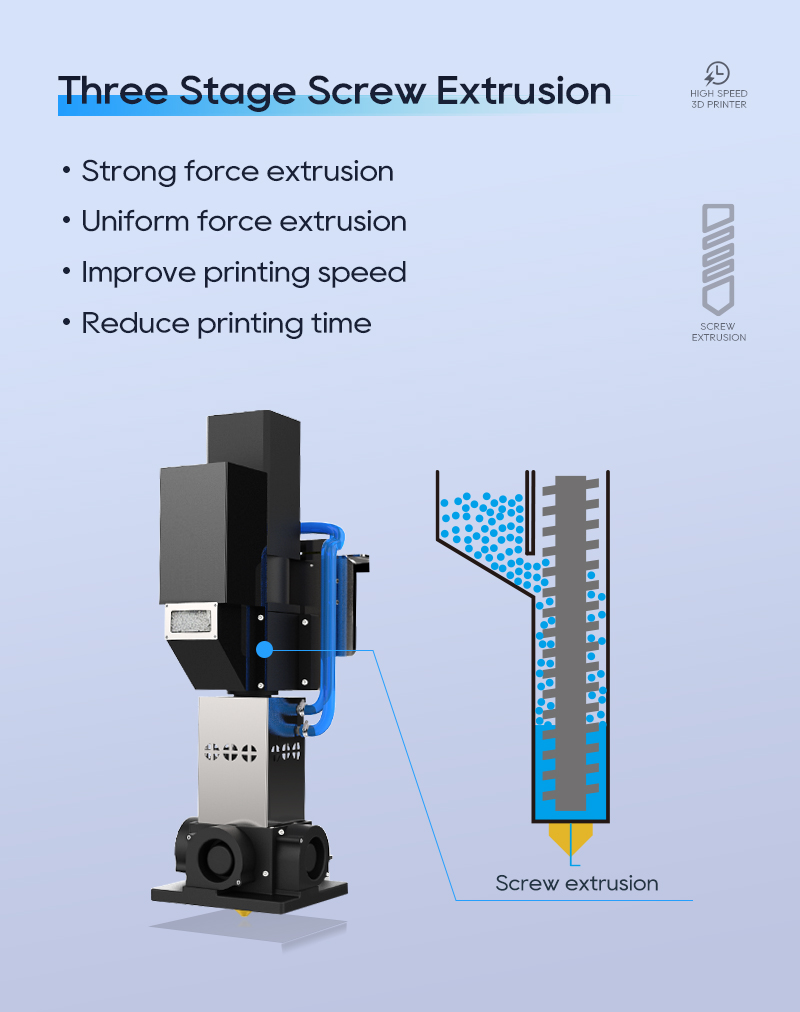

Three Stage Screw Extrusion

*Strong force extrusion

*Uniform force extrusion

*Improve printing speed

*Reduce printing time

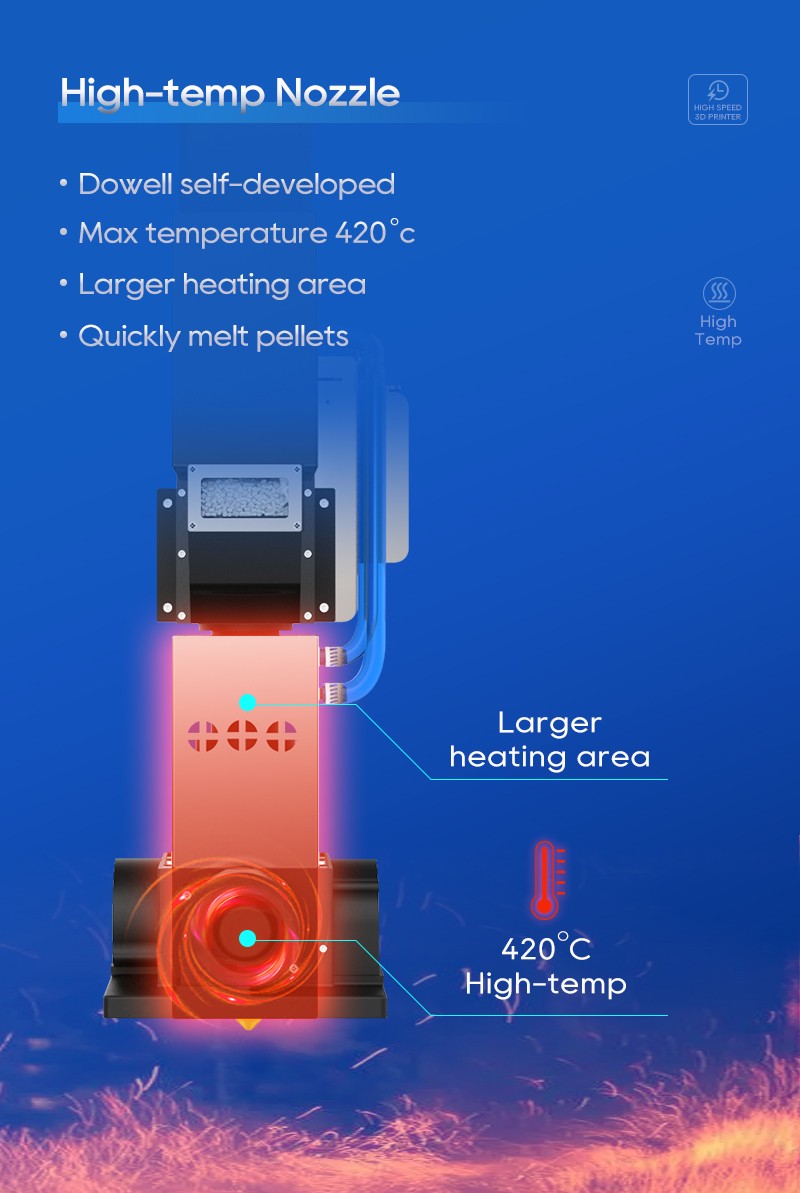

420℃ High-Temp Nozzle

*DOWELL3D Self-Developed

*Max temperature 420℃

*Larger heating area

*Quickly melt pellets

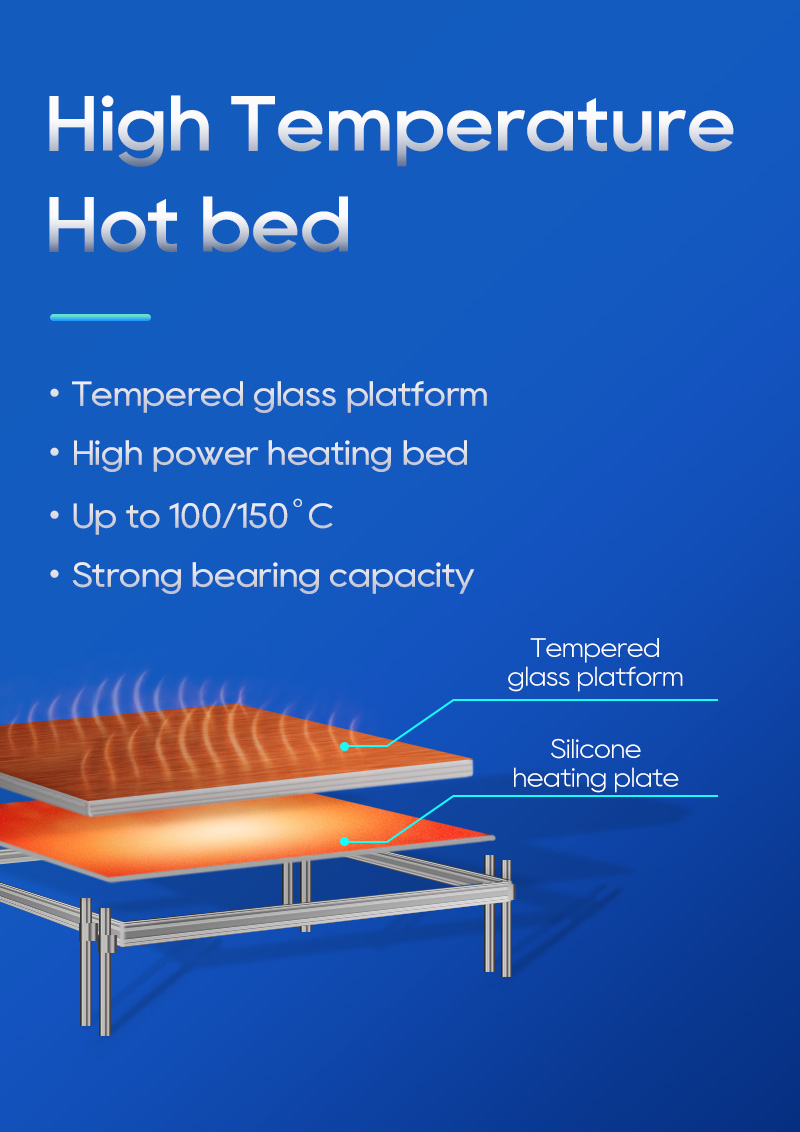

High Temperature Hot Bed

*Tempered glass platform

*High power heating bed

*Strong bearing capacity

*Up to 100/150C(optional)

Anti-collision & Auto resume from power off

*Nozzle has self-developed, inner part has anti-collision structure, which can effective

avoid nozzle collision caused by wrong operation.

*Power failure protection, continue printing after recovery.

Water Cooling & Heat Dissipation

*Self-developed *Separate water cooling system *Rapid heat dissipation

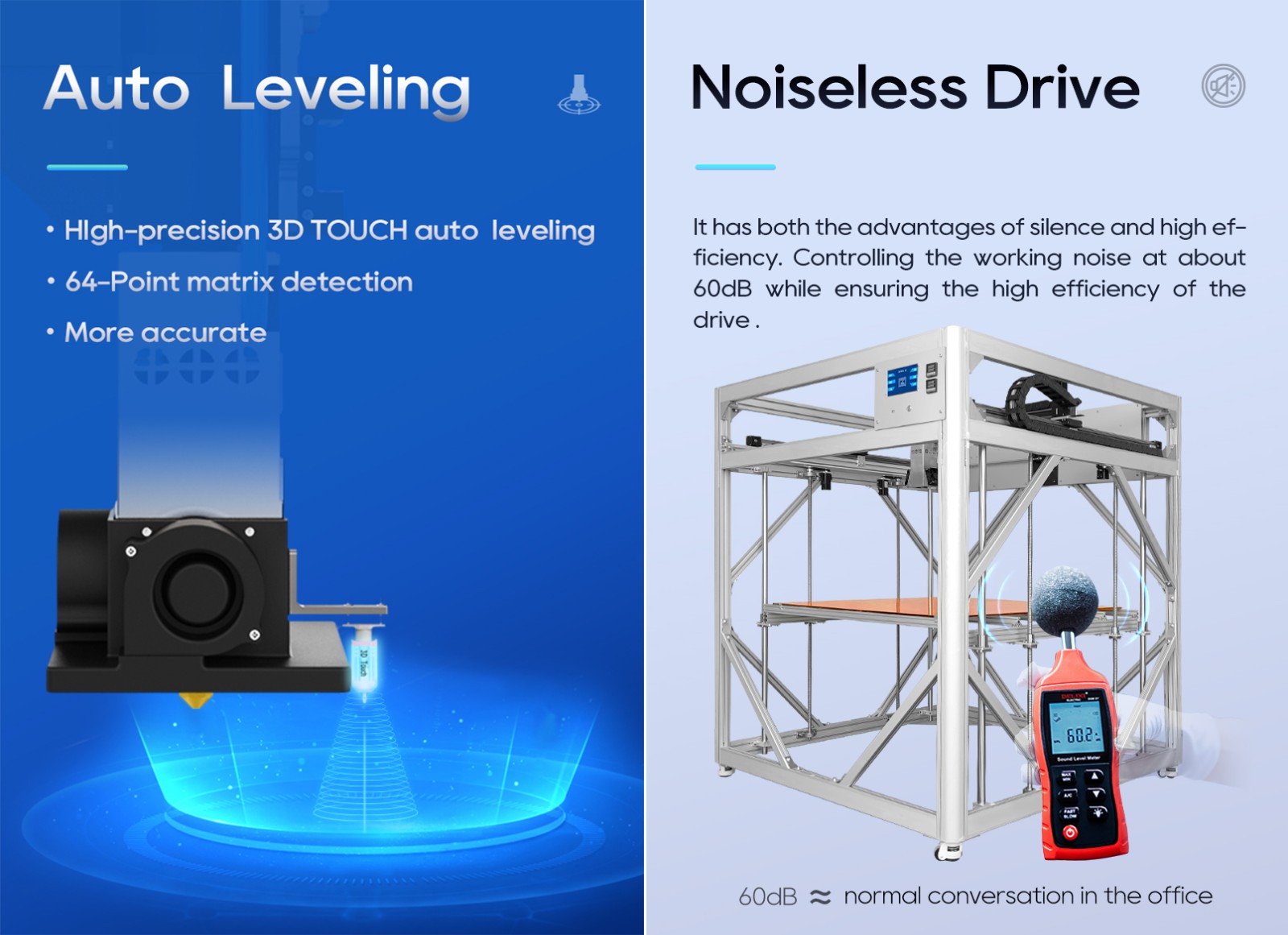

*Auto Leveling: High-precision 3D TOUCH auto leveling, coupled with 64-Point ma-

trix detection, ensures more accurate results.

*Noiseless Drive: It has both the advantages of silence and high efficiency. Contro-

lling the working noise at about 60dB while ensuring the high efficiency of the drive.

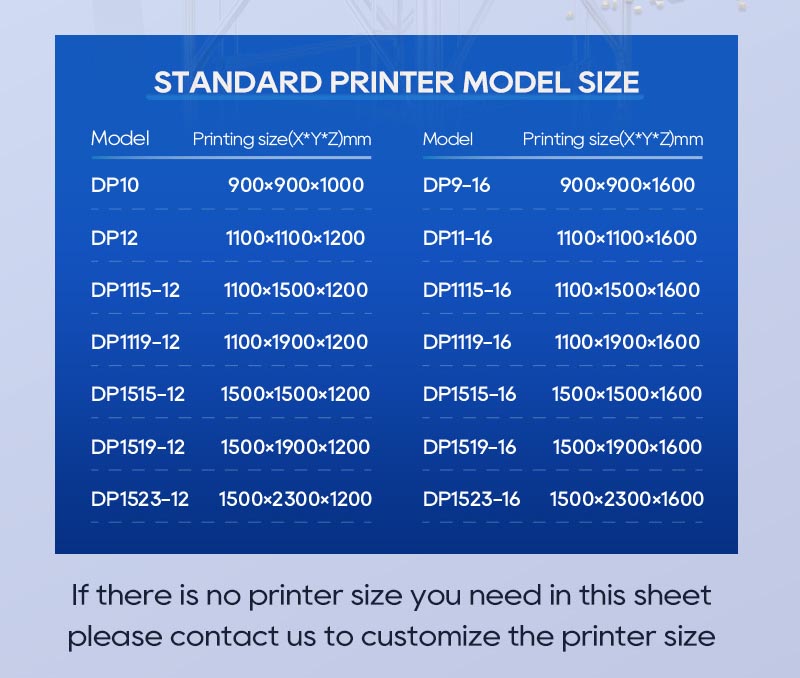

*The above are standard dimensions.

*In addition to these sizes, you can contact us for customized dimensions

tailored to your specific.

Promises: *One year warranty *Lifetime maintenance *Factory direct sales *Quality

assurance *Technical support

Customizaton options

In addition to its fundamental features, DOWELL3D printers are also equip-

ped with customizable functionalities, allowing users to tailor the printer to

your specific needs.

*Auto Feeding System.

*Customization printing size.

*Constant 60°c temperature enclosure: Standard pellet printer is open frame, we also

provide an option of 0-60C constant temp enclosure. There is independent heaters

and temperature control system.

*Klipper system: Support Wifi connection for remote control, Real-time adjustment

of Z off-set, acceleration, and enjoy the free software upgrade service.

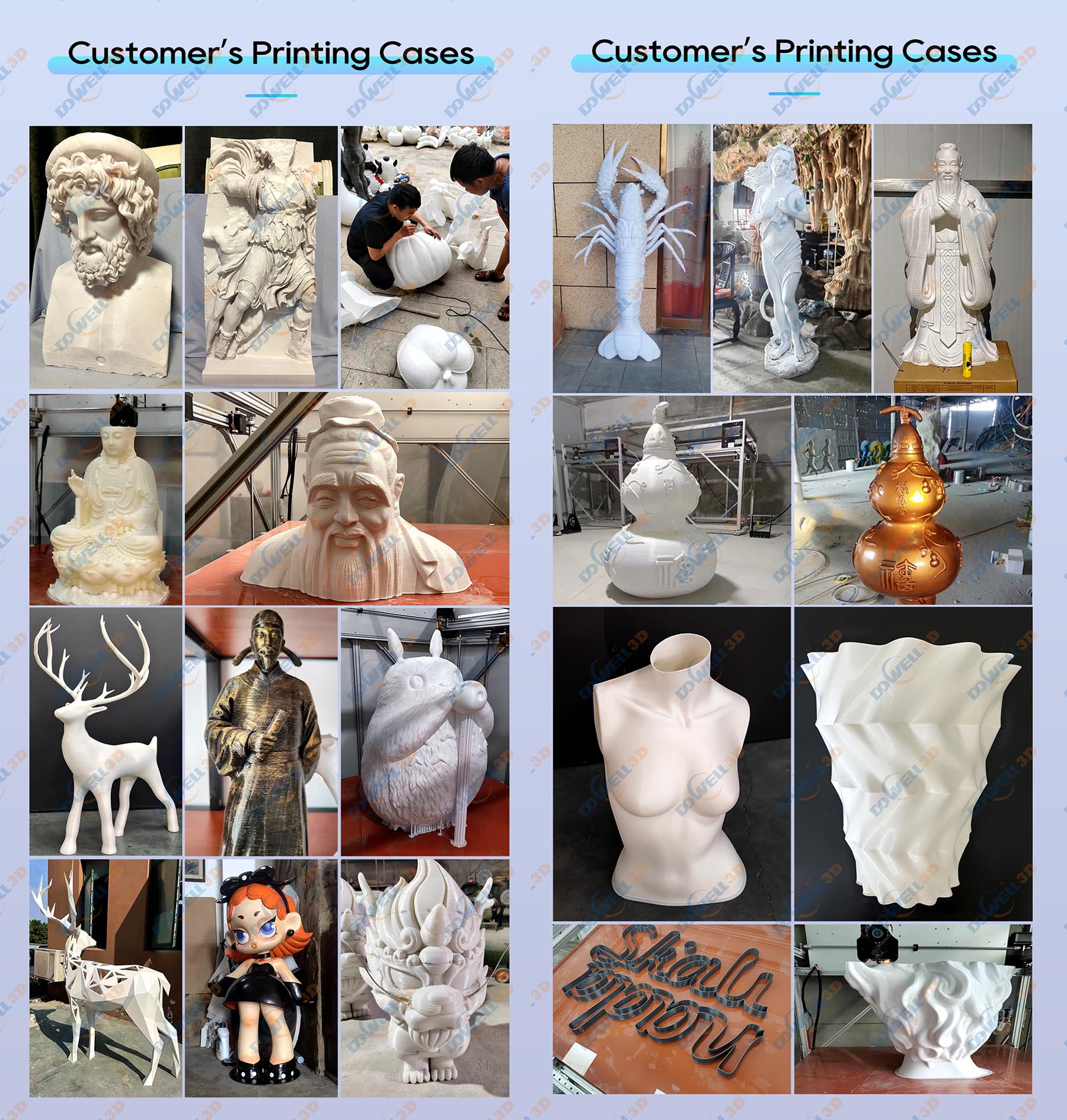

Customer's Printing Cases of DOWELL3D Printer

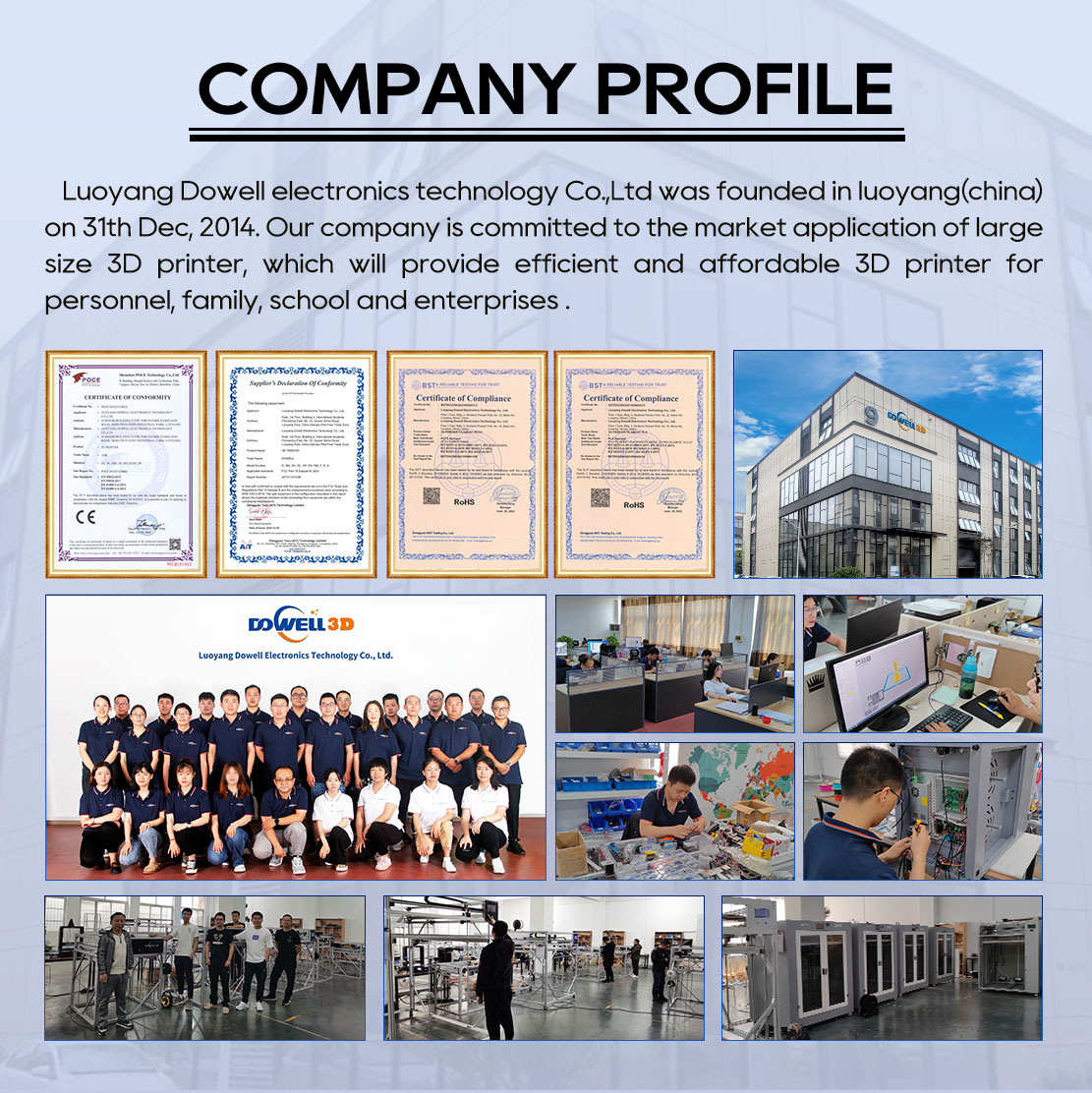

Company Profile & Certifications of DOWELL3D

Print with Ease, Innovate Infinitely!

DOWELL3D, a manufacturer with a decade of expertise in R&D, production, and global

export of large-scale industrial 3D printers, proudly offers a diverse range of user-friendly,

large-format 3D printers tailored for industrial applications. Our extensive lineup features

space-efficient designs and intelligent operating systems, ensuring versatility for produc-

ing top-notch parts in any environ-ment. Whether you're crafting factory tools, prototypes,

or end-use components, DOWELL3D printer stands out as a robust, cost-effective solution

for manufacturing large-scale, high-quality parts.

FAQ

1-Are you a factory?

Yes, we are a directly manufacturer focus on developing and produce large industrial 3d printers.

2-Payment method

T/T (Bank transfer), Paypal, West union, Credit card, Wechat pay, Ali Pay, T/T

3-Shipping method

DHL, UPS, Fedex, TNT, sea shipping, air freight, by train.

4-What's your lead time?

If the product you order is our standard model, lead time is around14 days; or else lead time is negotiable.

5-How do you guarantee the quality of the printer?

We have 100% tests before shipment. We will supply photos and video of tests before shipment.

We can guarantee that our 3D printer will have absolutely no quality problems before shipment.

Then we will arrange the shipping under the confirming.